In today’s world, precision cutting technologies have revolutionized the manufacturing industry, enabling businesses to create intricate designs and shapes with utmost accuracy and efficiency. Among the various cutting methods available, CNC, laser, and waterjet cutting technologies have emerged as the go-to choices for many professionals. Each method offers its own set of advantages and applications, making it crucial to understand their differences and select the right method for your specific project needs. In this ultimate guide, we will delve into the world of CNC, laser, and waterjet cutting, demystify their technologies, and help you make informed decisions when it comes to precision cutting.

Table of Contents

Comparing CNC, Laser, and Waterjet Cutting Technologies

Understanding the Differences in Precision Cutting Methods

Precision cutting methods are designed to achieve accuracy and consistent results, but they utilize different mechanisms to achieve this goal. CNC cutting technology relies on computer numerical control, which utilizes a combination of machining and programming to automate the cutting process. Laser cutting, on the other hand, uses a high-powered laser beam to cut through various materials, providing intricate and precise cuts. Waterjet cutting, meanwhile, utilizes a high-pressure stream of water mixed with an abrasive substance to precisely cut through materials.

What sets these technologies apart is the materials they can handle. CNC cutting is versatile and can be used for a wide range of materials, including wood, plastic, and metal. Laser cutting is highly effective for materials such as acrylic, wood, and metal, while waterjet cutting excels in cutting materials like stone, glass, and composites.

Selecting the Right Cutting Method for Your Project

Choosing the right cutting method for your project involves considering various factors such as material type, intricacy of design, and project requirements. For projects that require a high level of precision and intricate details, laser cutting is often the preferred choice. Laser cutting offers minimal kerf width (the width of material removed) and heat-affected zone (HAZ), resulting in clean cuts with minimal distortion. This method is especially popular in industries like signage, jewelry making, and automotive.

If your project involves materials that are sensitive to heat, such as plastics or certain metals, waterjet cutting may be the optimal solution. Waterjet cutting produces no heat-affected zone and can cut through thick materials with ease, making it suitable for applications like aerospace, architectural designs, and industrial parts manufacturing.

On the other hand, CNC cutting provides a cost-effective and efficient option for projects that don’t require intricate details or extremely fine tolerances. CNC routers are widely used in woodworking, cabinetry, and general fabrication, offering versatility and reliability.

Exploring the Unique Capabilities of Waterjet Cutting

Waterjet cutting stands out with its ability to cut through a variety of materials without generating heat. This makes it the ideal choice for projects that involve heat-sensitive materials or when minimal material distortion is desired. With waterjet cutting, you can achieve precise cuts with minimal tolerances, allowing for intricate designs and complex shapes.

One of the key advantages of waterjet cutting is its versatility in handling different materials. Whether you’re working with metals, stone, glass, or composites, waterjet cutting can produce clean and accurate cuts without the risk of altering the material properties. This technology has found applications in industries such as aerospace, automotive, and architectural design, where precision and quality are paramount.

Furthermore, waterjet cutting offers the advantage of being a cold cutting process. Unlike laser cutting, which can generate heat and potentially affect the material properties, waterjet cutting ensures that the material remains unaffected by heat. This is particularly beneficial when working with delicate materials that are prone to warping or melting under high temperatures.

Another notable feature of waterjet cutting is its ability to cut through thick materials with ease. While laser cutting may struggle with thicker materials, waterjet cutting can effortlessly handle materials of varying thicknesses. This makes it an excellent choice for projects that require cutting through thick metals or stone, where other methods may prove less effective.

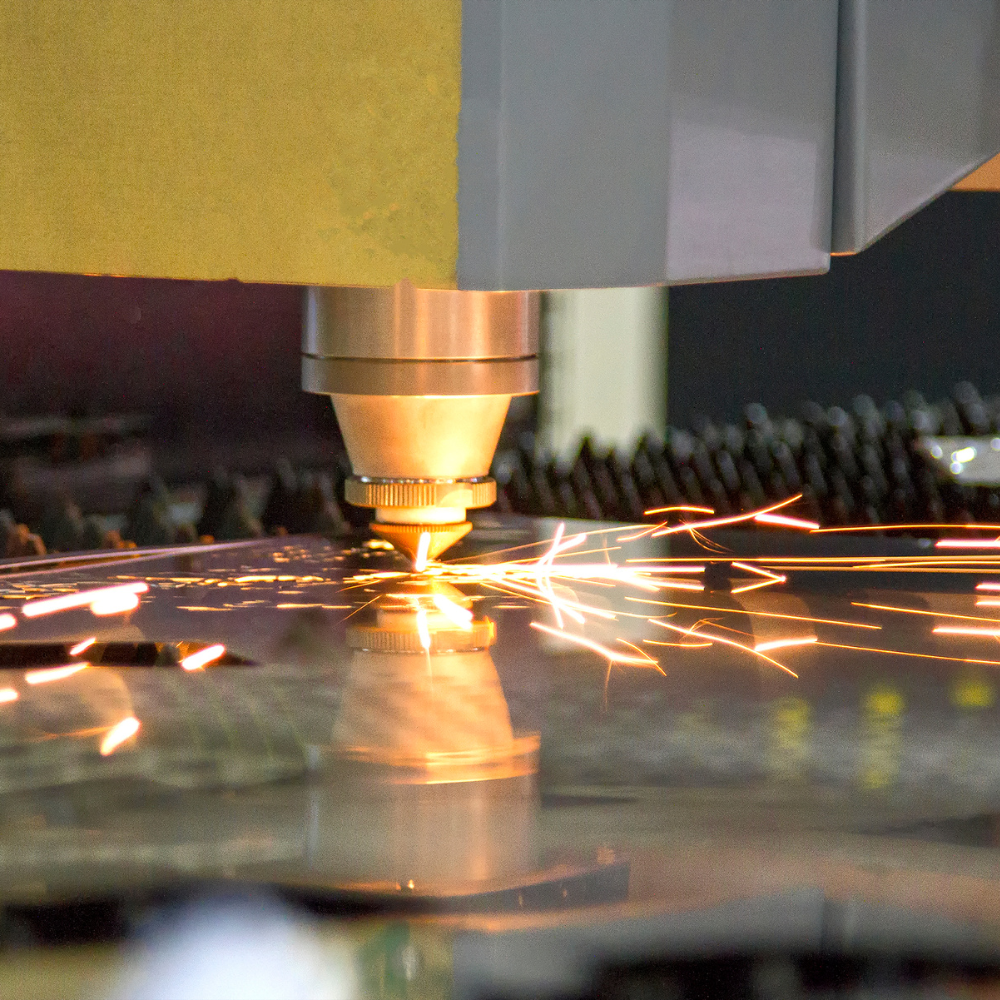

Demystifying Laser Cutting Technology

Mastering Kerf and HAZ in Laser Cutting

When it comes to laser cutting, two critical factors to understand are kerf and heat-affected zone (HAZ). Kerf refers to the width of material removed during the cutting process. Laser cutting offers extremely narrow kerf widths, allowing for precise cuts and minimal material wastage. The HAZ, on the other hand, refers to the area around the cut that is affected by heat. With proper settings and control, laser cutting can minimize the HAZ, ensuring minimal distortion and preserving the structural integrity of the material.

With advancements in laser cutting technology, operators can now achieve even finer tolerances and produce intricate designs. This makes laser cutting highly sought after in industries such as automotive, aerospace, and electronics, where precision and accuracy are crucial.

But let’s delve deeper into the world of laser cutting and explore some fascinating details that make this technology so remarkable.

Did you know that laser cutting machines use a focused beam of light to cut through materials? The laser beam is so intense that it vaporizes or melts the material, creating a clean and precise cut. This process is incredibly fast and can be completed in a matter of seconds, making laser cutting a highly efficient method.

Another interesting aspect of laser cutting is the ability to achieve intricate designs and patterns. The laser beam can be controlled with exceptional precision, allowing for the creation of complex shapes and fine details that would be challenging to achieve with traditional cutting methods. This versatility opens up a world of possibilities for designers and manufacturers, enabling them to bring their creative visions to life.

Optimizing Materials for Laser Cutting Projects

To ensure successful laser cutting projects, it is important to understand which materials are most suitable for this cutting method. Laser cutting works exceptionally well with materials such as acrylic, wood, paper, fabric, and various types of metals. These materials offer excellent results due to their ability to efficiently absorb the laser energy.

However, it’s worth noting that some materials may require additional precautions or adjustments. For instance, reflective materials like aluminum may need specialized coatings or different laser frequencies to ensure proper cutting. By understanding the characteristics of your materials and consulting with professionals, you can optimize your laser cutting projects for the best results.

Now, let’s take a closer look at the unique properties of some of these materials and how they interact with laser cutting technology.

Acrylic, for example, is a popular choice for laser cutting due to its transparency and versatility. The laser beam passes through the acrylic, creating a smooth and polished edge. Wood, on the other hand, offers a natural and rustic aesthetic when laser cut. The laser beam interacts with the wood fibers, resulting in a charming burnt effect that adds character to the final product.

When it comes to metals, laser cutting can be a game-changer. The precision and speed of laser cutting make it ideal for intricate metal designs. From stainless steel to brass, laser cutting can create precise cuts with minimal distortion, allowing for the production of high-quality metal components.

Insider Tips for a Successful Laser Cutting Experience

To make the most of your laser cutting experience, consider the following insider tips:

- Choose the appropriate laser power and frequency for the material you are working with.

- Ensure proper ventilation and safety measures, as laser cutting involves fumes and potential fire hazards.

- Optimize your design files for laser cutting by converting them to vector format.

- Perform test cuts on scrap material to fine-tune settings and ensure desired results.

- Regularly maintain and clean your laser cutting machine to maintain optimal performance.

By following these tips, you can enhance your laser cutting experience and achieve outstanding results. Remember, laser cutting is a powerful technology that combines precision, speed, and versatility, opening up a world of possibilities for various industries and creative endeavors.

Unveiling the World of CNC Routing

What to Anticipate with CNC Routing Services

CNC routing services offer a wide range of capabilities and advantages for projects of all sizes. This technology utilizes computer-controlled routers to precisely cut, drill, and shape various materials. With CNC routing, you can achieve consistent results, exact replication of designs, and high production rates.

One of the key benefits of CNC routing is its versatility in handling different materials. Whether you’re working with wood, plastic, foam, or composite materials, CNC routers can handle a wide range of materials, providing precise cuts and intricate designs. This makes it a popular choice in industries such as woodworking, cabinetry, and furniture manufacturing.

Enhancing CNC Routed Parts with Value-Added Services

To take your CNC routed parts to the next level, consider incorporating value-added services. These services can enhance the appearance, functionality, and durability of your products. Some common value-added services include:

- Edgebanding: Applying a decorative edge to conceal the exposed edges of the material.

- Laminating: Adding a layer of protective film or veneer to enhance durability and aesthetics.

- Finishing: Applying paint, stain, or other finishes to achieve the desired appearance.

- Assembly: Joining multiple CNC routed parts to create a final product.

By leveraging value-added services, you can elevate the quality and value of your CNC routed parts, ensuring they meet your specific project requirements.

Delving into the Precision of Waterjet Cutting

Top Materials Ideal for Waterjet Cutting Applications

Waterjet cutting technology offers exceptional precision and versatility, making it suitable for a wide range of materials. Some of the top materials ideal for waterjet cutting include:

- Metal alloys: Waterjet cutting can handle various types of metals, including stainless steel, aluminum, and titanium.

- Stone: From granite countertops to intricate marble sculptures, waterjet cutting can achieve precise cuts on a variety of stone materials.

- Glass: Waterjet cutting allows for intricate glass designs while minimizing the risk of shattering or cracking.

- Composites: With its ability to cut through layers of different materials, waterjet cutting is ideal for composites used in aerospace, automotive, and construction industries.

By harnessing the power of waterjet cutting, you can achieve precise cuts, intricate designs, and smooth finishes on these materials, ensuring your projects meet the highest standards of quality.

Selecting the Best Cutting Method for Your Project’s Needs

As you navigate the world of CNC, laser, and waterjet cutting technologies, it’s essential to understand the unique capabilities and applications of each method. By considering factors such as material type, project requirements, and desired precision, you can select the best cutting method for your project’s needs. Whether you require the precision of laser cutting, the versatility of CNC routing, or the accuracy of waterjet cutting, investing in the right technology will ensure optimal results and help you bring your creative visions to life.

With the knowledge gained from this ultimate guide, you are now equipped to make informed decisions and harness the power of CNC, laser, and waterjet cutting technologies. So go ahead, embrace the world of precision cutting, and unlock endless possibilities for your projects.