Stainless steel is a reliable and durable material that has become increasingly popular in various industries. It’s used in fabrication of machinery, buildings, vehicles, utensils, and many other items we use daily. Cutting stainless steel requires precision, expertise, and attention to safety measures. In this article, we’ll explore the basics of cutting stainless steel and explore TDH Manufacturing’s expertise in the field.

Table of Contents

Understanding Stainless Steel: A Primer for Beginners

Stainless steel is a metal alloy consisting of iron, chromium, and nickel. It is a versatile material that is used in a wide range of industries, including construction, automotive, and aerospace. One of the key benefits of stainless steel is its resistance to corrosion, staining, and rust, which makes it an attractive material for various applications.

However, not all stainless steel is created equal. There are many different grades of stainless steel, each with its own unique properties and uses. It is important to understand the grade of stainless steel you’re working with, as it will affect the selection of cutting tools and techniques.

The most common grades of stainless steel are 304, 316, and 430. Grade 304 is the most commonly used stainless steel and is ideal for food and beverage equipment, medical devices, and chemical containers. It has excellent corrosion resistance and is easy to clean and sanitize.

Grade 316 is another popular grade of stainless steel, commonly used in marine and chemical processing applications. It has a higher resistance to corrosion than grade 304, making it ideal for use in harsh environments.

Grade 430 is a ferritic stainless steel that is commonly used in consumer goods and kitchen equipment. It is less corrosion-resistant than grades 304 and 316, but is more affordable and easier to work with.

When working with stainless steel, it is important to use the correct cutting tools and techniques to ensure a clean and precise cut. For example, when cutting grade 304 stainless steel, it is recommended to use a saw blade with a high-speed steel tooth geometry and a variable pitch, as this will provide a smooth and accurate cut.

In addition to its practical uses, stainless steel is also a popular material for jewelry and fashion accessories. Its durability and resistance to tarnishing make it a popular choice for watches, bracelets, and necklaces.

Overall, stainless steel is a versatile and durable material that is used in a wide range of applications. By understanding the different grades of stainless steel and their properties, you can choose the right material for your project and ensure a successful outcome.

The Basics of Cutting Stainless Steel

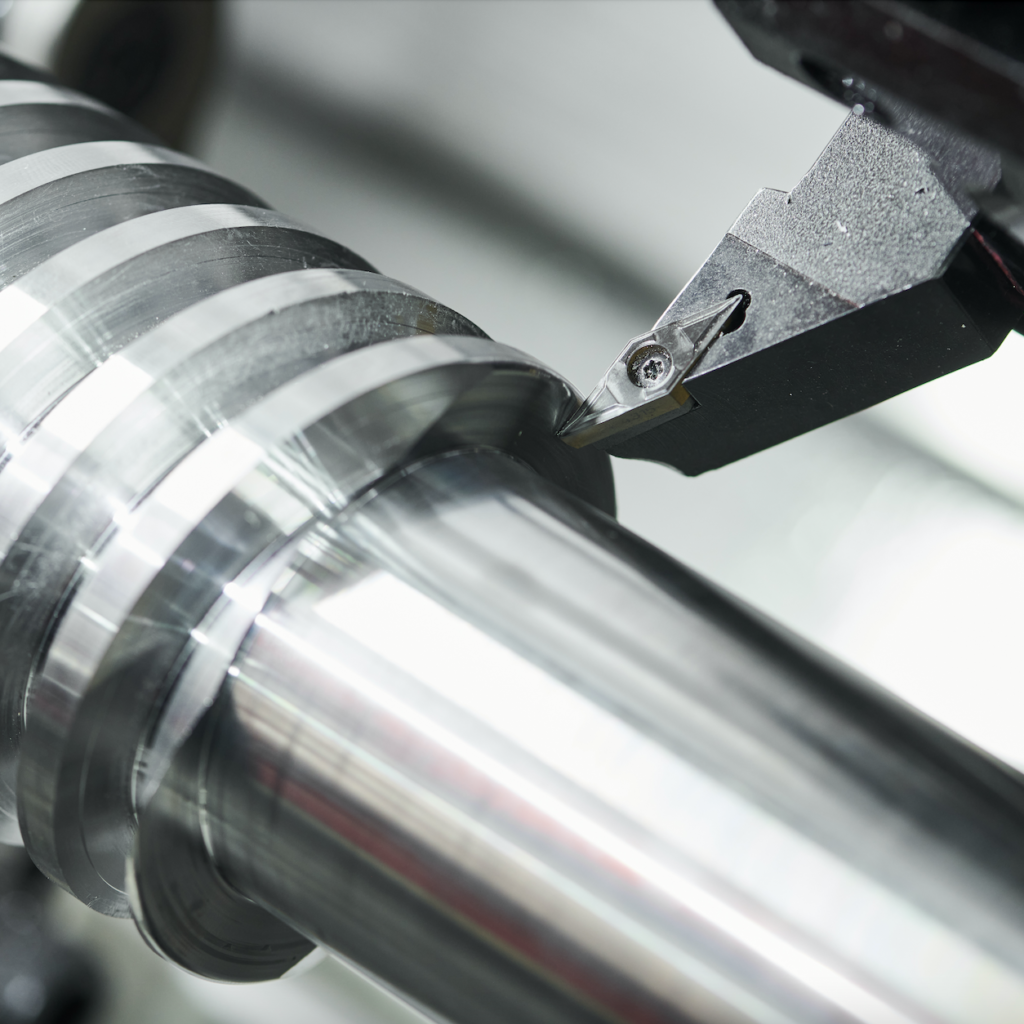

Cutting stainless steel is a task that requires precision and skill. It’s a material that is known for its toughness and durability, which is why it’s commonly used in industrial and construction projects. In this article, we’ll be discussing the basics of cutting stainless steel, including the tools and techniques used.

The Right Tools for the Job

When it comes to cutting stainless steel, using the right tool is crucial. Here are the most commonly used cutting tools:

- Power saws: Power saws are a popular choice for cutting stainless steel. Band saws, circular saws, and plasma cutters are the most commonly used power saws. They are ideal for thick sections of stainless steel but can be expensive to operate.

- Cutting torches: Cutting torches, such as oxy-fuel and plasma torches, are another option for cutting stainless steel. They are suitable for large sections of stainless steel but can be dangerous if not used correctly.

- Shears: Shears are perfect for thin sections of stainless steel. Hand-held shears and power shears are the most commonly used types of shears. However, they can lead to frayed edges.

Each tool has its advantages and disadvantages. It’s important to select the right tool for the job and use it correctly to achieve the desired outcome.

Cutting Techniques

There are several cutting techniques commonly used when cutting stainless steel:

- Straight cutting: Straight cutting involves cutting in a straight line. This technique is commonly used for cutting large sections of stainless steel.

- Circular cutting: Circular cutting involves cutting in a circular pattern. This technique is commonly used for cutting holes in stainless steel.

- Curved cutting: Curved cutting involves cutting curves and irregular shapes. This technique is commonly used for creating custom shapes and designs.

The technique used depends on the desired outcome and the shape and size of the stainless steel section. It’s important to use the right technique to achieve a clean and precise cut.

In conclusion, cutting stainless steel requires the right tools and techniques. By selecting the right tool and using the right technique, you can achieve a clean and precise cut. Whether you’re working on an industrial or construction project, cutting stainless steel is a task that requires precision and skill.

Why Cutting Stainless Steel is Different: Challenges and Solutions

Cutting stainless steel is a complex process that requires precision and expertise. Unlike other materials, stainless steel is a hard and tough metal that poses unique challenges to cutting. Its high thermal conductivity and low thermal expansion coefficient make it difficult to cut with traditional tools and techniques.

Stainless steel is commonly used in a variety of industries, including construction, automotive, and aerospace, due to its durability and resistance to corrosion. However, cutting this material requires specialized knowledge and equipment to ensure a high-quality finish.

One of the main challenges of cutting stainless steel is its hardness. Stainless steel is much harder than other metals, such as aluminum or mild steel, which makes it more difficult to cut. This can result in slower cutting speeds, increased wear on the cutting tool, and a higher risk of tool breakage.

In addition to its hardness, stainless steel also has a high thermal conductivity, which leads to heat buildup in the cutting tool. This can cause the tool to become discolored and lose its cutting edge, resulting in a poor-quality finish. To overcome this challenge, it is important to use the right cutting tool, speed, and technique.

Using a high-quality cutting fluid is also essential when cutting stainless steel. Cutting fluids can enhance the cutting process by reducing friction and heat buildup, improving the lifespan of the tool, and ensuring a high-quality finish. There are many different types of cutting fluids available, including oils, emulsions, and synthetic fluids, each with their own advantages and disadvantages.

Another technique that can be used when cutting stainless steel is to use a laser cutting machine. Laser cutting machines use a high-energy laser beam to cut through the material, resulting in a precise and clean cut. This technique is particularly useful when cutting complex shapes or patterns in stainless steel.

In conclusion, cutting stainless steel is a challenging process that requires specialized knowledge and equipment. To ensure a high-quality finish, it is important to use the right cutting tool, speed, and technique, as well as a high-quality cutting fluid. By following these guidelines, it is possible to achieve a precise and clean cut in even the toughest of materials.

Tools of the Trade: Selecting the Right Equipment for Cutting Stainless Steel

Selecting the right equipment for cutting stainless steel is critical in achieving a quality cut. TDH Manufacturing has a wide range of cutting equipment to meet different needs. Our equipment includes:

- High definition plasma cutters for clean and precise cuts

- Water jet cutting machines for intricate shapes and thick sections of stainless steel

- Laser cutters, which can cut a range of material thicknesses with no material distortion or warping

- CNC shearing and punching machines for high-speed cutting of thin sections of stainless steel

TDH Manufacturing’s Proven Methodology: Our Unique Approach to Cutting Stainless Steel

TDH Manufacturing has a unique methodology for cutting stainless steel. Our approach is to combine the right tool and technique with a customized cutting plan for each section of stainless steel. We identify the grade of stainless steel and the desired outcome, then select the right tool and cutting fluid to achieve a high-quality cut with minimal discoloration and distortion.

Safety First: Precautions when Cutting Stainless Steel

Stainless steel cutting can be a hazardous activity if safety measures are not taken seriously. It’s crucial to follow safety guidelines and to wear personal protective equipment, such as safety glasses and gloves. It’s also essential to ensure that the cutting area is free of clutter and that the cutting tools are used according to instructions.

TDH Manufacturing’s Expert Advice for Mastering Stainless Steel Cutting

TDH Manufacturing has years of experience in cutting stainless steel. Our expert advice for mastering stainless steel cutting includes:

- Identifying the grade of stainless steel and selecting the right cutting tool and technique

- Using the appropriate cutting fluid to reduce friction and heat buildup

- Ensuring that the cutting tool is in good condition before use

- Following safety guidelines and wearing personal protective equipment

By using these recommendations, you can achieve high-quality cuts with minimal discoloration and distortion and reduce cutting downtime and expenses.

The Role of Cutting Stainless Steel in Local Industry

Cutting stainless steel plays a critical role in local industry. Stainless steel is used in machinery, buildings, electrical appliances, vehicles, and many other applications. TDH Manufacturing’s high-quality cutting services contribute to the growth and success of local businesses, ensuring their products are of the highest standard.

Why Choose TDH Manufacturing: Your Partner for Cutting Stainless Steel

TDH Manufacturing is a reliable and experienced provider of cutting stainless steel services. We have a team of experts who understand the nuances of cutting stainless steel and are committed to providing high-quality services. We use state-of-the-art equipment and cutting-edge techniques to ensure that our clients achieve the best possible results. Partner with us today and experience the benefits of our exceptional cutting services.