Imagine a world where pump hoist design is revolutionized, making water well operations more efficient and environmentally friendly. This is not a dream, but a reality being realized through the use of ECAD (Electrical Computer-Aided Design) technology. In this article, we will take a deep dive into TDH Manufacturing‘s innovative approach to pump hoist design and explore how ECAD is transforming the industry.

Table of Contents

Introduction to ECAD in the Water Well Industry

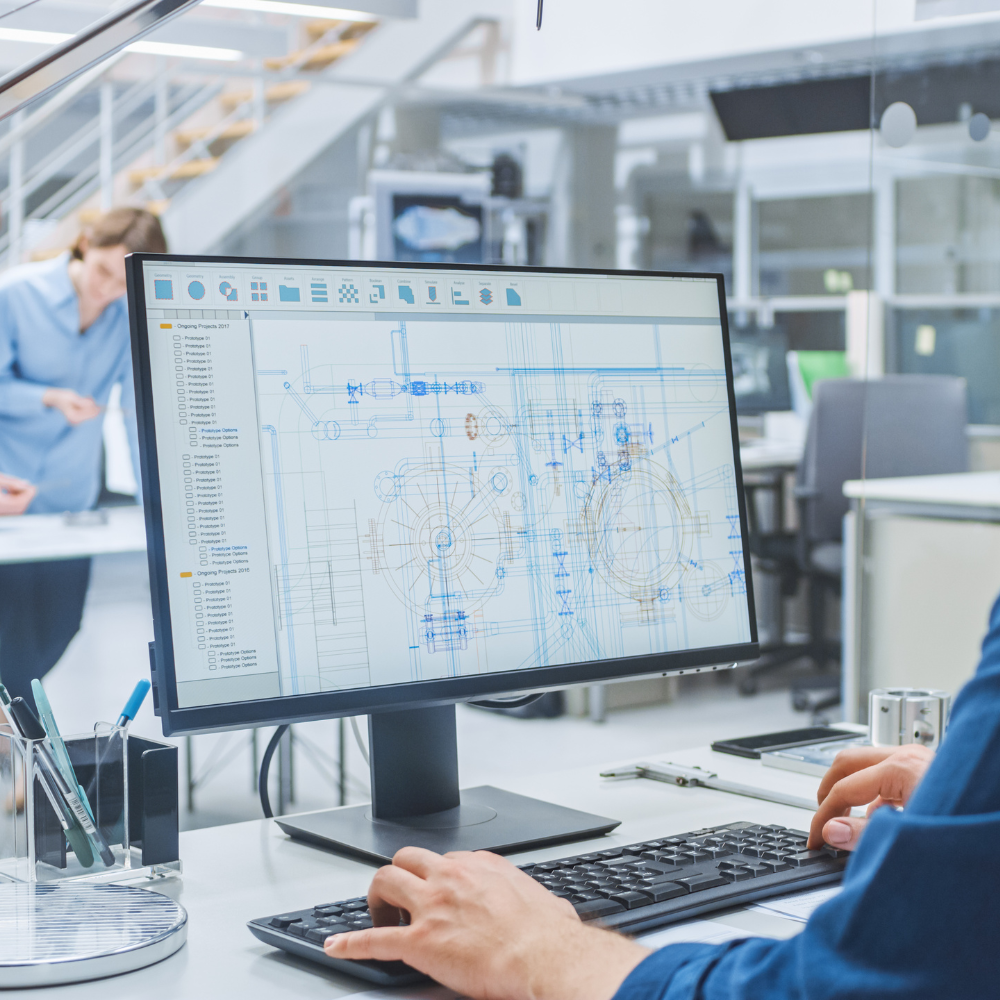

ECAD has emerged as a game-changer in the water well industry, offering a host of benefits for manufacturers and end-users alike. By leveraging sophisticated computer software, ECAD brings precision and efficiency to the design and production processes. It enables TDH Manufacturing to create customized pump hoists that meet the unique requirements of their customers.

But what exactly is ECAD, and how does it work? ECAD combines electrical and design engineering into one powerful tool. It allows designers to create precise electronic schematics, generate detailed 3D models, simulate system performance, and generate accurate bills of materials.

Moreover, ECAD software plays a crucial role in ensuring compliance with industry standards and regulations. For water well manufacturers, adhering to specific guidelines is paramount to guaranteeing the safety and reliability of their products. ECAD tools provide features that help designers incorporate necessary safety measures, such as overload protection and fail-safe mechanisms, into their systems.

Additionally, ECAD facilitates collaboration among different teams involved in the water well production process. Through cloud-based platforms and real-time sharing capabilities, engineers, electricians, and project managers can work seamlessly together, streamlining communication and enhancing overall project efficiency.

Revolutionizing Pump Hoist Design with ECAD: A Peek into TDH Manufacturing’s Technological Edge

TDH Manufacturing has been at the forefront of incorporating ECAD into their pump hoist design process. By embracing this cutting-edge technology, they have revolutionized the industry and set new standards for efficiency and innovation. Let’s take a closer look at how ECAD is transforming pump hoist manufacturing.

The integration of ECAD has streamlined TDH’s design process, eliminating manual errors and reducing the time required for design iterations. With ECAD, engineers can quickly test different configurations, evaluate performance metrics, and find optimal solutions.

But the benefits of ECAD go beyond design efficiency. By accurately simulating the behavior of the pump hoists in different conditions, TDH can fine-tune their products for maximum performance. This results in better reliability, increased energy efficiency, and reduced maintenance costs for their customers.

Furthermore, the implementation of ECAD has empowered TDH Manufacturing to enhance collaboration among their design teams. Through real-time sharing of design data and simulations, engineers can work together seamlessly, brainstorming ideas and solving complex challenges more effectively. This collaborative approach has led to a culture of innovation within the company, driving continuous improvement and pushing the boundaries of pump hoist technology.

Additionally, ECAD has enabled TDH to offer customized solutions to their clients with greater precision. By leveraging the detailed insights provided by ECAD simulations, TDH can tailor their pump hoists to meet specific requirements, whether it be in terms of load capacity, speed, or environmental factors. This level of customization not only enhances customer satisfaction but also solidifies TDH’s reputation as a leader in the industry.

Understanding ECAD in Manufacturing Processes

ECAD plays a crucial role in different stages of the pump hoist manufacturing process. From initial concept design to final assembly, TDH utilizes ECAD to ensure a seamless and efficient workflow. Let’s delve into each stage to get a comprehensive understanding of ECAD’s contribution.

Concept Design: ECAD allows TDH engineers to visualize and iterate on various design options virtually before the physical prototyping stage. This enables them to choose the most effective design path and minimize costly redesigns. By leveraging ECAD tools, TDH can explore innovative ideas and concepts, pushing the boundaries of pump hoist design to meet evolving industry demands and standards.

- Concept Design: ECAD allows TDH engineers to visualize and iterate on various design options virtually before the physical prototyping stage. This enables them to choose the most effective design path and minimize costly redesigns.

- Electrical Design: ECAD software helps TDH engineers create accurate and detailed electrical schematics, ensuring the integrity and functionality of the pump hoists.

- 3D Modeling: With ECAD, TDH engineers can generate lifelike 3D models of the pump hoists, allowing them to visualize the entire system and identify any potential clashes or interference.

- Simulation: TDH utilizes ECAD’s simulation capabilities to evaluate the performance of their pump hoists under different operating conditions. This helps them optimize the design for superior efficiency and reliability.

- Manufacturing Documentation: ECAD generates accurate bills of materials and assembly instructions, ensuring that the manufacturing process is precise and error-free.

Electrical Design: ECAD software provides TDH engineers with a platform to not only create electrical schematics but also simulate electrical systems to ensure optimal performance and safety. By utilizing ECAD for electrical design, TDH can streamline the integration of electrical components within the pump hoists, enhancing overall functionality and reliability.